DEPAC, your trusted manufacturer of mechanical seals, is entering the digital era. With innovative Industry 4.0 services powered by the KIWAI platform, we bring intelligence, traceability, and connectivity to your equipment.

Our mission is to make industrial assets smarter—combining mechanical precision with digital intelligence. Whether for predictive maintenance, compliance, or lifecycle tracking, DEPAC’s digital services give your equipment a digital heartbeat.

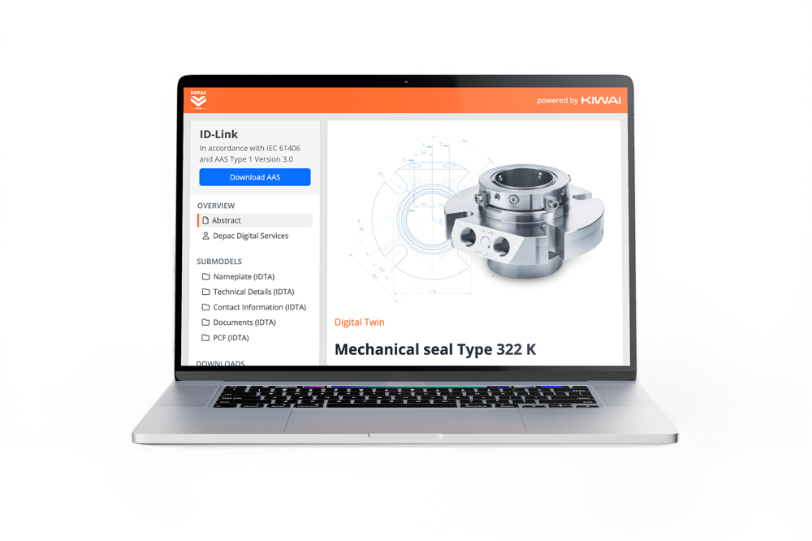

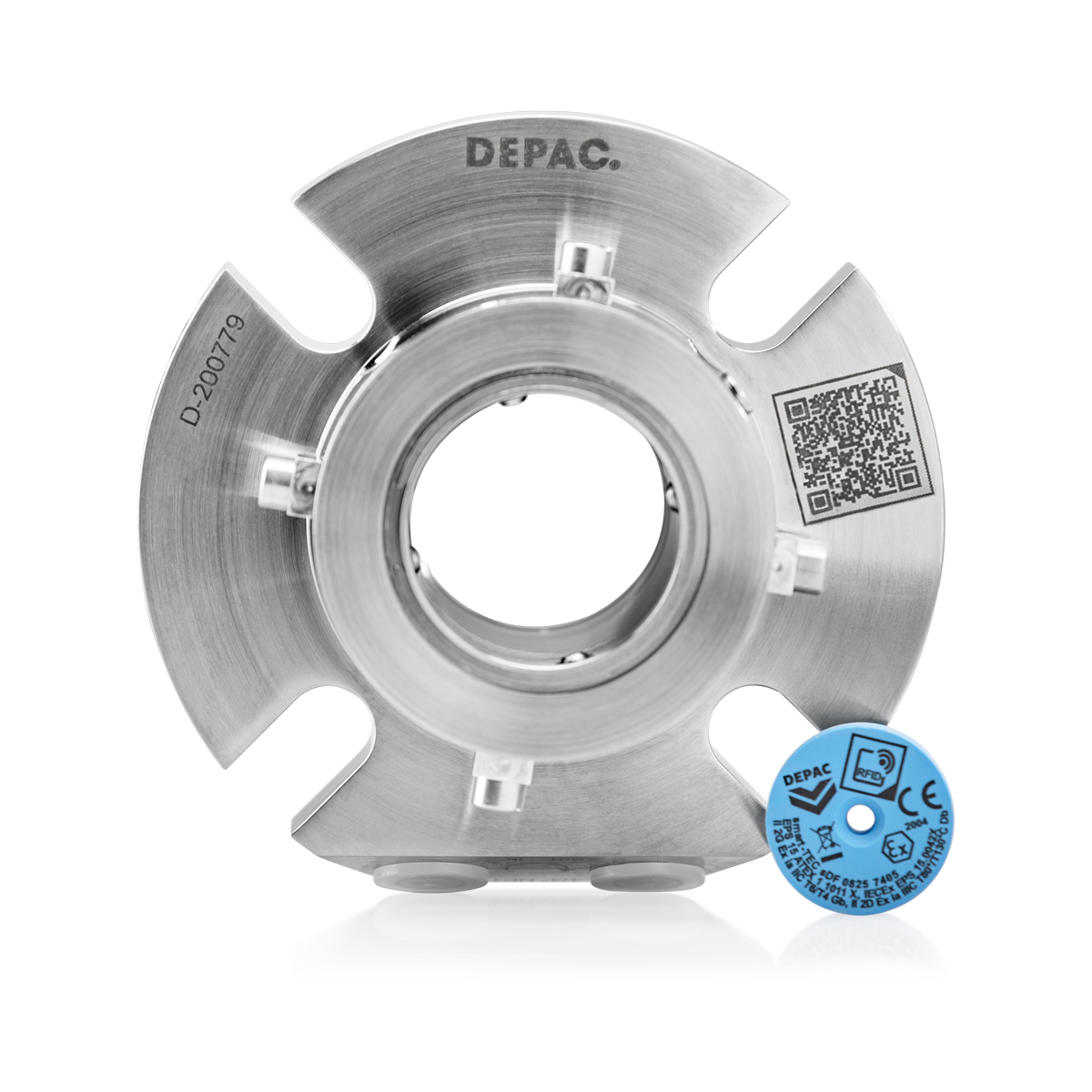

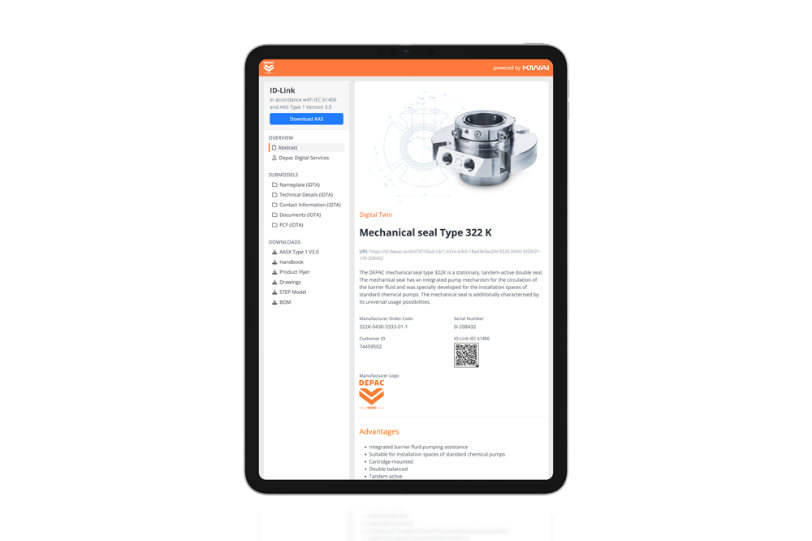

What it is: IDLink gives each product a unique digital identity, just like a passport. This enables traceability across supply chains, ensures regulatory compliance, and unlocks data-driven services.

Benefits:

What it is: A Digital Twin is a dynamic, real-time d igital replica of your physical product. DEPAC’s Digital Twins provide actionable insights that keep your assets performing at their best.

Use cases:

What it is: The Asset Administration Shell (AAS) is the Industry 4.0 standard for representing asset data. DEPAC uses AAS to structure product data in a modular, machine-readable format—ready for integration into modern ecosystems.

Why it matters: